-

View Mobile Number -

savio@gemsons.com

Contact Us

Phone : +91-22-26851590

Call Us : View Primary Number

Quality

Gemsons is a pioneer manufacturer of precision machined components & assemblies. We at Gemsons are committed to continual growth with a prime focus on customer satisfaction. We strive to produce quality products and still be competitive & efficient.

Upgrading technology appropriate to the changing needs of the customer.

We at Gemsons Precision Engineering (P) Ltd. have a stringent quality check at every level i.e. inward, in-process and the final stage, thereby reducing rejection and maintaining high quality levels, as per our quality plans.

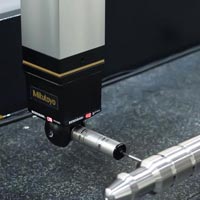

Our workshop is equipped with the best IMT equipment such as Mitutoyo CNC CMM Machines with Continuous scanning software & Renishaw PH10MQ probe head & continuous scanning probe SP25M with scanning and touch-trigger probing in a single probe system., Mitutoyo Programmable Height Station, Electronica Height Gauges, Mitutoyo Contracer for contour measurement, Profile Projectors, Roughness Testers, Digimatic 1micron Micrometers, 3-point Micrometers, Air Gauges, Slip Boxes, Dial Indicators etc.

Calibration of gauges is carried out in-house. Instruments and Equipments are calibrated at NABL approved laboratories traceable to National Standards [NPL, India].

We are having In-house NDT Testing facilities like Ultrasonic tests and Dye Penetrate test with Level II inspectors .

We follow the APQP & PPAP Level - III Procedure for New product development.

We extensively use the Problem solving tools like 8D, DMAIC, FMEA, Why-Why Analysis.

We constantly encourage all the employees for their active involvement in continues improvements through kaizen projects to improve the productivity and Quality levels.

Periodic training for skill and overall personality development are planned and executed for all the employees.'

Gemsons has its Inhouse State of Art Measuring equipment ranging from CNC CMM, Contracer, Profile Projector, PMI for material grade identification, Ultrasonic testing to check for internal cracks, Thickness Measuring machine, Height Measuring Stations from Mahr and Mitutoyo, Trimos Height Masters, Slip Boxes, Digimatic 1micron Micrometers, 3-point Micrometers and Air Gauges for high tolerance parts. We also have our own capability to do NDT testing like Magnetic Particle, Die Penetrant , Radiography testing.

- Implementing a documented Quality Management System.

- Ensuring defect free products.

- Delivering on time, every time.

- Optimum resource utilization.

- Training, motivation& involvement of all the employees.

- Complying with all legal & applicable requirements related to the products.

- Continual Improvement in all QMS Processes.

- Defining & planning to achieve the quality objectives.

- Understanding & fulfilling the requirements of all interested parties.

Upgrading technology appropriate to the changing needs of the customer.

We at Gemsons Precision Engineering (P) Ltd. have a stringent quality check at every level i.e. inward, in-process and the final stage, thereby reducing rejection and maintaining high quality levels, as per our quality plans.

Our workshop is equipped with the best IMT equipment such as Mitutoyo CNC CMM Machines with Continuous scanning software & Renishaw PH10MQ probe head & continuous scanning probe SP25M with scanning and touch-trigger probing in a single probe system., Mitutoyo Programmable Height Station, Electronica Height Gauges, Mitutoyo Contracer for contour measurement, Profile Projectors, Roughness Testers, Digimatic 1micron Micrometers, 3-point Micrometers, Air Gauges, Slip Boxes, Dial Indicators etc.

Calibration of gauges is carried out in-house. Instruments and Equipments are calibrated at NABL approved laboratories traceable to National Standards [NPL, India].

We are having In-house NDT Testing facilities like Ultrasonic tests and Dye Penetrate test with Level II inspectors .

We follow the APQP & PPAP Level - III Procedure for New product development.

We extensively use the Problem solving tools like 8D, DMAIC, FMEA, Why-Why Analysis.

We constantly encourage all the employees for their active involvement in continues improvements through kaizen projects to improve the productivity and Quality levels.

Periodic training for skill and overall personality development are planned and executed for all the employees.'

Gemsons has its Inhouse State of Art Measuring equipment ranging from CNC CMM, Contracer, Profile Projector, PMI for material grade identification, Ultrasonic testing to check for internal cracks, Thickness Measuring machine, Height Measuring Stations from Mahr and Mitutoyo, Trimos Height Masters, Slip Boxes, Digimatic 1micron Micrometers, 3-point Micrometers and Air Gauges for high tolerance parts. We also have our own capability to do NDT testing like Magnetic Particle, Die Penetrant , Radiography testing.